Middleware Gamma 7

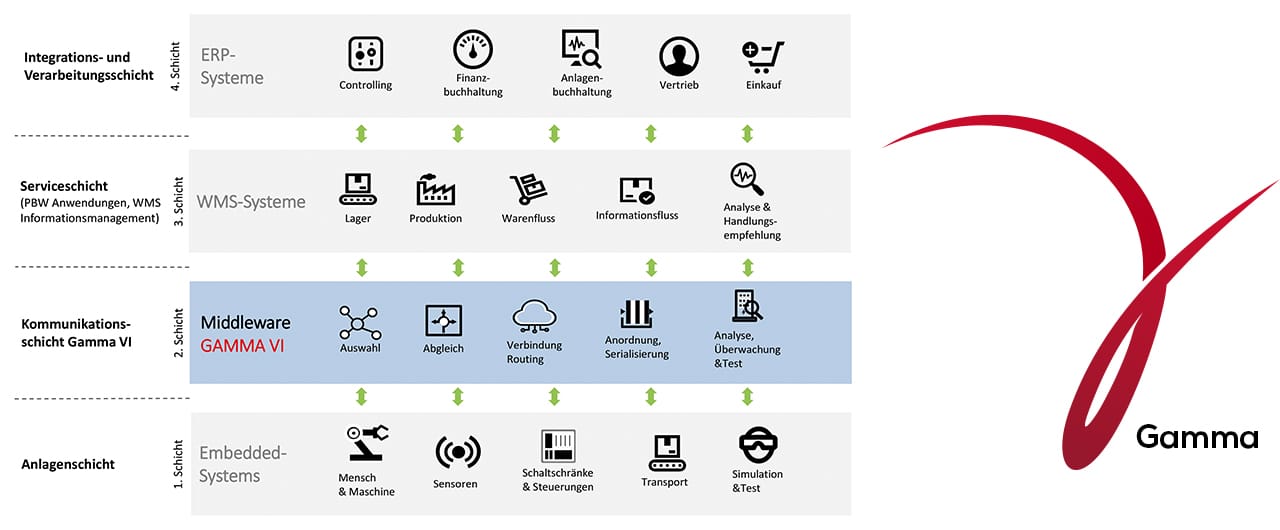

With the product Gamma 6 and Gamma 7 middleware solutions offer companies a comprehensive platform for automating standard processes and smoothly integrating complex data structures. The Gamma range of middleware is designed to efficiently manage systems, automate processes and ensure seamless communication between different components and locations – ideal for modern organisations that require future-oriented, scalable solutions.

With the Gamma 7 product solution, the developer has the opportunity to automate recurring standard tasks of processes and data connections. A product solution that independently controls and manages processes and data within your systems, supports you during development and remains open to new standards, simplifying maintenance and upgrades for your customers. A standardised platform for service-oriented test systems, end-to-end machine control systems or for production in line with Industry 4.0 requirements. Modular, expandable as required and independent of existing hardware.

The Gamma 7 communication and integration platform is now available in its seventh generation and is a tried-and-tested product that has been on the market for over 25 years and is constantly being developed and optimised. This so-called middleware platform is now used to digitise modern machine control systems, test systems and even entire factories in an extremely efficient manner.

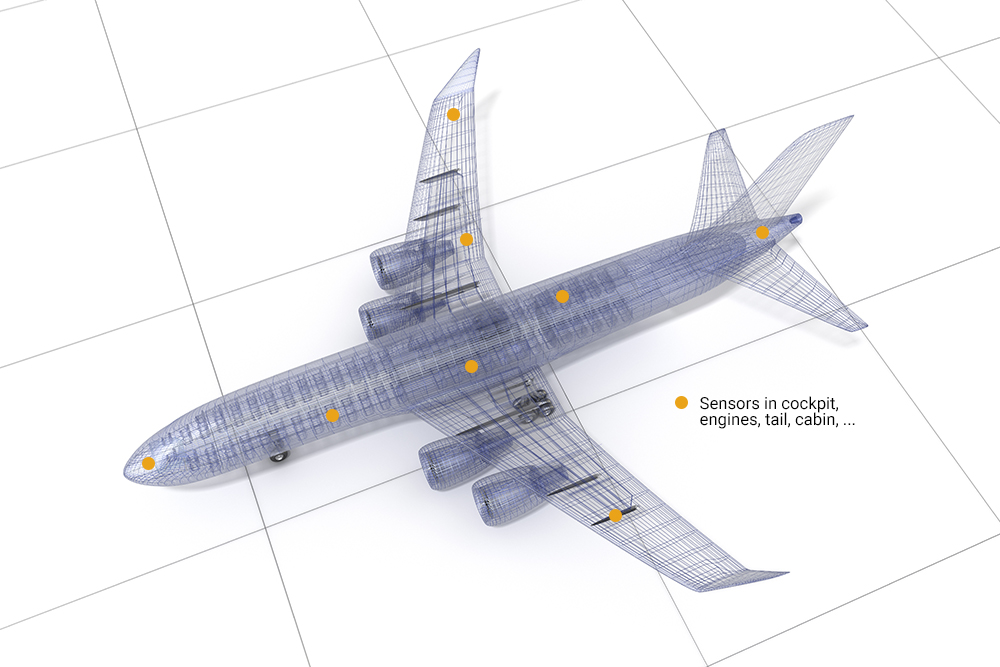

The most important action in the development of modern applications today is the merging of sensors and subsystems into a homogeneous platform. The resulting data model allows processes to communicate easily with each other and is simultaneously linked via the time model of the middleware. The Gamma platform supports all these important forms of data communication and is the ideal platform when functions and standardised interfaces need to be provided and linked centrally.

The middleware represents the ‘universal connector’ between different layers. Whether robots, sensors, PLCs, machines or tools – Gamma 7 always connects all areas in the optimum form of communication.The open system architecture combines different hardware and operating systems, networks, fieldbuses, sensors and actuators with a variety of tools and programming languages.

The Gamma communication and integration platform is now available in its seventh generation and is a tried-and-tested product that has been on the market for over 25 years and is constantly being developed and optimised. Whether robots, sensors, PLCs, machines or tools – Gamma always connects all areas in the optimum form of communication.The open system architecture combines different hardware and operating systems, networks, fieldbuses, sensors and actuators with a variety of tools and programming languages.

Gamma 7 - Overview of devices and areas of application

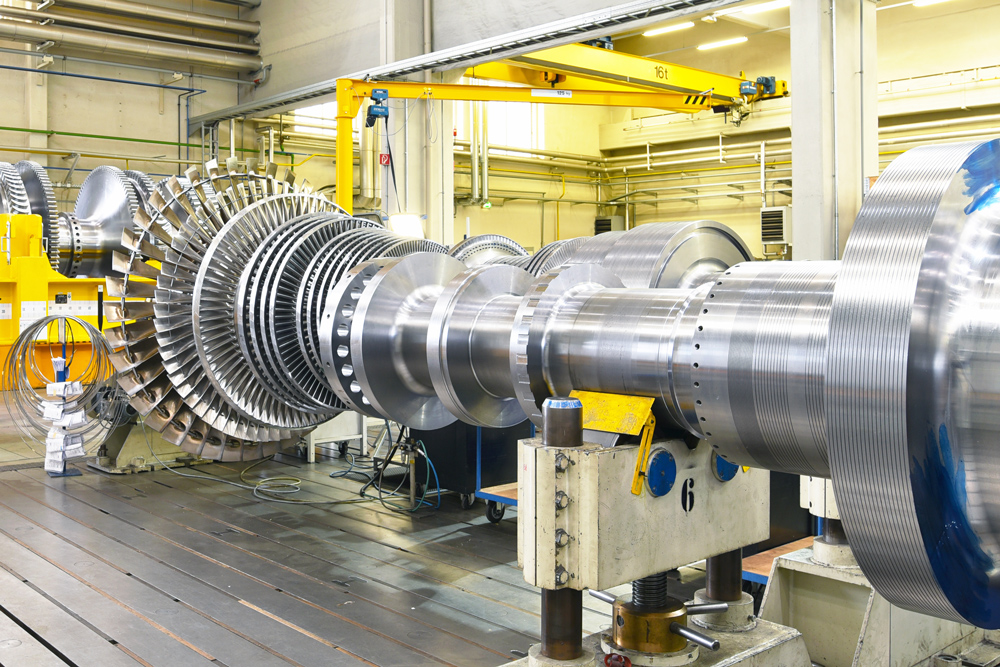

Gamma 7 is a powerful, flexible control and automation system that is used in a wide range of industries, from industrial production to aerospace. It enables precise control, monitoring, and data acquisition in real time and can be adapted to complex technical systems in a variety of ways.

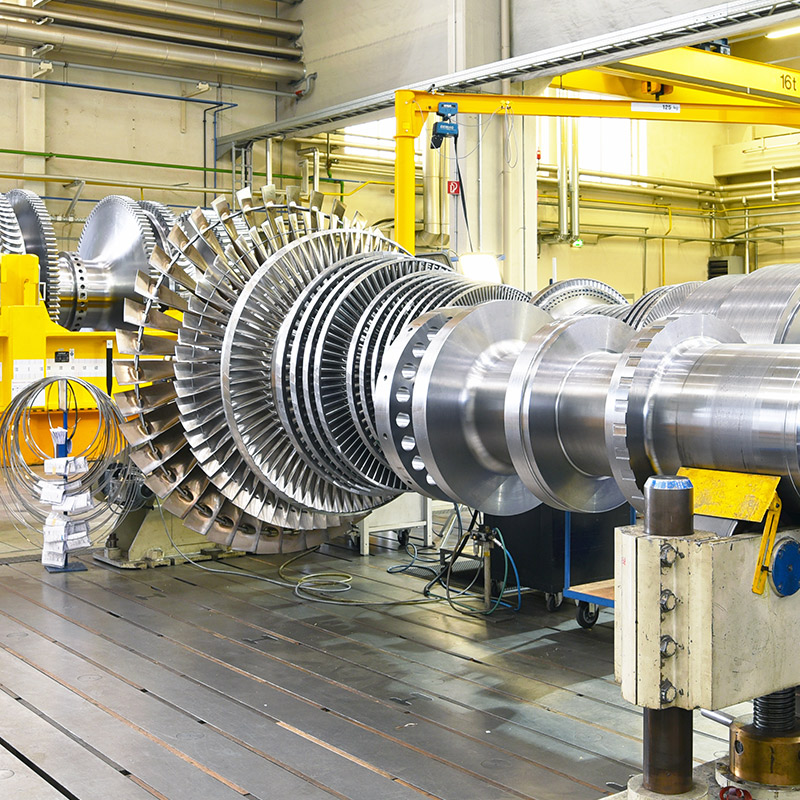

Industry and manufacturing

- Control of steel production plants

- Control of drill presses

- Fabric cutting machine with real-time control

- Grinding machine with Gamma real-time (1 ms cycle time)

- Moisture meter with Gamma surface connection

- Manufacture of LEDs

- Calendar printing machine with Gamma

- Light switch control

- Fiber optic production for antennas

- Scaffolding robots

- Development and production test benches

- Flexible production lines with robots from different manufacturers

- Control of modular production plants and assembly lines

- Additive manufacturing (3D printing) including post-processing and quality assurance

- Smart maintenance systems with condition monitoring and data analysis

- Energy-optimized production control (e.g., dynamic machine shutdown during peak loads)

- Integration and modernization of older CNC machines (retrofit)

- Quality assurance with AI-supported sensor fusion (camera, force, temperature)

Aerospace

- Test bench for satellite power units

- A350 remote test bench

- Airbus cabin pressure test bench

- Engine test bench

- Eurofighter flight stick test bench (software and mechanics)

- Slat/flap control computer for A320

- Data concentrator computer for A320

- Development test bench for aircraft landing gear

- Research test bench for universities (e.g., Institute of Aerospace Systems)

- Satellite communication

- HIL/SIL simulations for flight control and navigation computers

- Test systems for satellites, power supply, and communication

- Real-time monitoring of ground stations and flight tests

- Control and data evaluation for drone or robot swarms

Traffic and transport

- Measuring wheel set for ICE trains (TÜV acceptance test bench):

- Testing of wheel sets in the carriage

- Measurement of rail quality

Energy and environmental technology

- Control and monitoring of wind, solar, and hydroelectric power plants

- Smart grid gateways for grid optimization and energy storage

- Water and waste treatment plants with process monitoring

- Biogas plants with automatic control of feed, fermentation, and purification

- Recycling plants with AI-based sensor technology (camera, X-ray, weight)

Medicine and life sciences

- Robotic surgical and laboratory automation systems

- Proton and radiation therapy systems with integrated control and data security

- Sterile goods reprocessing with process monitoring and traceability

- Medical test benches (pumps, sensors, prostheses)

- Hospital logistics (transport and medication robots)

- Proton therapy control for cancer patients

- Research test benches in aerospace technology

Logistics and administration

- Warehouse management systems in the pharmaceutical industry

- Use of different inventory types

- Inventory control for counts performed

- Inventory overview

- Warehouse occupancy

- Work stocks in the warehouse

- Creation and management of transport points

- Creation and management of a transport route matrix

Agriculture and food production

- Autonomous farm robots for sowing, cultivation, and harvesting

- Automated milking systems with sensors for milk quality and hygiene

- Real-time coordination of multiple harvesters or tractors

- Smart irrigation systems with weather and soil data

- Control of feeding robots, silo systems, and mixing systems

- Greenhouse automation (climate, irrigation, nutrient dosing)

Construction and robotics

- Scaffolding, concreting, and welding robots on construction sites

- Control of tunnel boring machines with real-time sensor data

- Autonomous surveying drones for large construction sites

- Research and AI applications

- Real-time test benches for materials, energy, and vehicle research

- Cyber-physical laboratories at universities

- Sensor fusion for multi-robot or swarm systems

- Edge AI integration directly on the machine

Automotive and mobility

- Test benches for e-mobility components (batteries, inverters, chargers)

- Test systems for autonomous driving (radar, LiDAR, camera)

- Simulation and hardware-in-the-loop tests for control units (brake-by-wire, steer-by-wire)

- Fleet management for autonomous commercial vehicles

Other innovative fields of application

- Interactive robotics installations in museums or at trade fairs

- Automated warehouses in pharmacies or clinics

- Smart home test systems (lighting, energy, security)

- Offshore platforms with sensor and drive monitoring under extreme conditions

Middleware

Every modern computer system can be described in layers. The top layer is usually the application that is based on an operating system (2nd layer), which itself runs on the hardware (3rd layer) and controls and communicates with it.

Middleware based test systems

Whether aviation, automotive, rail or automatization – nothing works today without thorough testing. We support you in development as well as in environmental and production testing.

Industrial engineering and automation

The mechanical engineering industry is increasingly turning to the Gamma VI middleware platform. It is the fastest and most flexible solution to integrate systems.

Project execution and facility modernization

For more than two decades we have not only offered platforms and tools, but also extensive engineering and development services.

Branch solutions

Development of new test systems as well as modernization of existing and construction of new development and production test systems and for globally active companies.