Digital twin

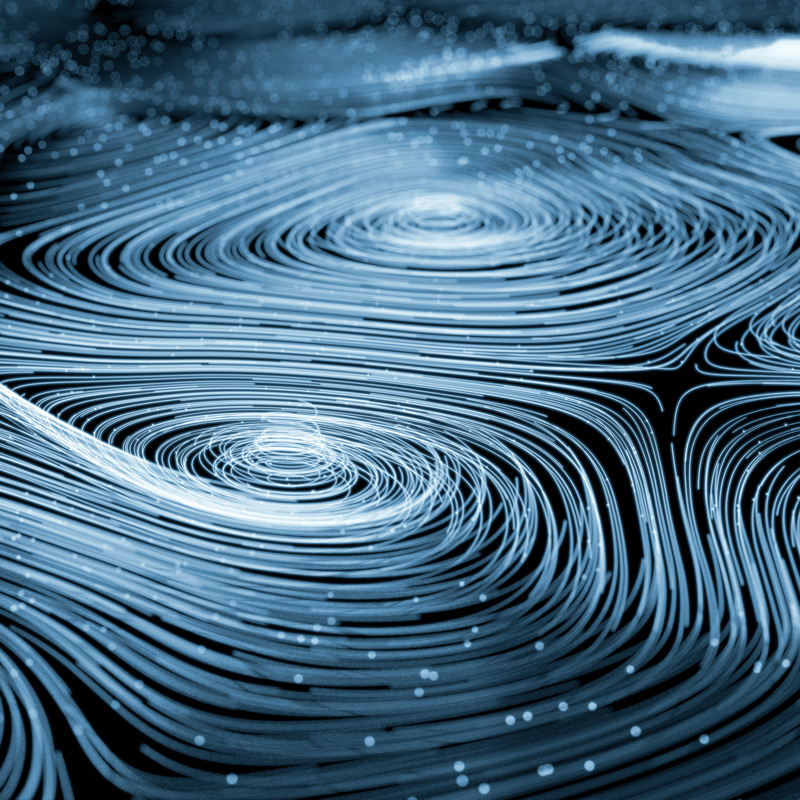

Digital twin = Abstract data layer

A digital twin is an abstract data layer above with which the state, characteristics and behaviour of a subordinate object can be visualised, analysed and adapted.

The virtual double has the same characteristics as the real object, which is equipped with sensors and delivers real-time information to the virtual image.

Extensive simulation and test functions on the virtual level enable the further implementation of digitization not only on site, but also in the office. This prevents disturbances in the production, delivers a significantly higher software quality and enables a sustainable long-term maintenance of the software on the digital twin.

Goals and tasks in the use of digital twins

- Direct access to the production machines in the production mode

- Providing extensive analysis and simulation data

- Simulation of production

- Control of order processing

- Analysis of the production process

- Virtual implementation

- Facility management

- Maintenance process

- Simulation and monitoring of energy management

- Simulation of the individual production machines in the entire process

- Monitoring the entire life cycle of a product

- Understand and deal with problems before they occur

- Detecting product defects in the simulation

- Higher quality

- Significant reduction of production costs through providing and evaluating real-time data. Direct access to manufacturing and production during the runtime environment.