LogiMAT 2024

Die sich ständig verändernden Märkte erfordern eine flexible und innovative Logistik. Prozesse müssen kontinuierlich überwacht und optimiert werden. Dies erfordert ein sensibles Gespür aus einer Fülle von Angeboten die Produkte und Lösungen zu identifizieren, mit denen Sie genau Ihre innerbetrieblichen Prozesse optimieren.

Das Warehouse Management System Proway Business World versetzt Sie in die Lage, Ihre Wertschöpfungskette effizient, präzise und schnell zu gestalten. Dies gewährleistet eine kontinuierliche Verbesserung von Qualität, Kundenzufriedenheit und Umsatz.

Besuchen Sie uns vom 19. – 21. März 2024 auf der LogiMAT in Stuttgart.

Sie finden uns in Halle 8 / Stand 8G78

Wir freuen uns auf Ihren Besuch

Prowaynachten

Wir wünschen Ihnen und Ihrer Familie besinnliche Feiertage, verbunden mit Gesundheit, Glück und beruflichem Erfolg für das Jahr 2024.

Viele Grüße

Ihr Proway-Team

Energiemanagement - sichtbar einfach

ENERGIEMANAGEMENT - SICHTBAR EINFACH

Energiemanagement ist die systematische Planung, Durchführung, Überwachung und Verbesserung von Maßnahmen zur Steigerung der Energieeffizienz und zur Reduzierung der Energiekosten in Kommunen, Energieversorgern, Stadtwerken, Industriebetrieben, Unternehmen oder verschiedenen Organisationen.

Grundvoraussetzung für ein erfolgreiches Energiemanagement liegt in der genauen Erfassung der Verbrauchsdaten und deren zeitlichem Verlauf für verschiedene Energieträger. In der Praxis scheitern schon viele Ansätze an der nicht gegebenen Transparenz. Das Proway Dashboard und seine über Jahre

bewährten Tools wie Gamma Blitz und Gamma Zauberwürfel bieten Ihnen hier eine robuste Lösung für ein effektives Energiemanagement.

Gamma Blockchain Connector

Gamma Blockchain Connector

Die Verwendung von Blockchain-Technologien hat in den letzten Jahren stark zugenommen, insbesondere im Bereich der Digitalisierung von Geschäftsprozessen. Eine der Anwendungen von Blockchain-Technologien ist die Absicherung kritischer Prozesse in der automatisierten Produktion und Logistik.

Die von Proway entwickelte Blockchain wird in die nächste Generation unserer Produktlösung Gamma 7 integriert. Die Blockchain-basierte Datenspeicherung wird als ein Bestandteil unserer etablierten Gamma Middleware eingeführt und um Krypto/Blockchain-Technologien erweitert.

Wir erarbeiten mit Ihnen gemeinsam die Implementierung von Gamma 7, um Ihnen die höchste Sicherheit in Ihrer Historie und Zukunft zu geben.

Erfahren Sie mehr unter: Blockchain

Warehouse Management System Proway Business World: Wareneingang

Warehouse Management Proway Business World: Wareneingang

Eine optimale Wareneingangsabwicklung ist der Grundstein für eine reibungslose Lagerverwaltung.

Fehler im Wareneingang haben üblicherweise signifikante Folgen und verursachen hohe Aufwände und Ablaufschwierigkeiten in den Folgeprozessen. Bleibt beispielsweise eine Mengenabweichung oder Verunreinigung im Wareneingang unentdeckt, kann dies zu einem Stillstand in der Kommissionierung führen. Die Palette muss gesperrt werden, zusätzlicher Nachschub oder gar Stornierungen sind erforderlich. Alternativ kann eine fehlerhafte Palettierung zu großen Umpackaufwänden in der Verladung führen.

Hohe Standards bei der Durchführung von Wareneingängen reduzieren derartige „hausgemachte“ Schwierigkeiten und sorgen somit für bessere und effizientere Folgeabläufe. Das Lagerverwaltungssystem Proway Business World (PBW) unterstützt mit seinen Funktionen das Etablieren und Einhalten entsprechender Standards – ohne die Wareneingangsaufwände unnötig zu erhöhen.

Dies beginnt bei einer verständlichen und übersichtlichen Verwaltung der Avise, vor, während und nach der Bearbeitung und geht bis hin zu flexiblen Strategien zur Ermittlung der optimalen Ausnutzung der Lagerbereiche. Aufgrund der flexiblen Konfigurationsmöglichkeiten des PBW lassen sich die Funktionen optimal mit den physischen Abläufen kombinieren und gemäß Ihren Bedürfnissen einrichten.

• Avisierung zur Planung der Eingänge und Mengen

• Qualitätsprüfungen und Qualitätssicherungsaufträge zu eingehenden Waren

• Palettierungsvorschläge zur Bildung optimaler Ladeeinheiten

• Lagerfindung zur Ermittlung passender Lagerbereiche

• Konfigurierbare Platzsuche zur Findung des optimalen Lagers, Gangs und Platzes

• Abläufe zur Annahme, Prüfung und Rückführung von Retouren

• Handling von Über- und Unterlieferungen

• Bewertung von Lieferanten

• Rückmeldung der Wareneingangsabwicklung an ERP-Systeme

Der Grundstein für eine effiziente und fehlerfreie Lagerabwicklung ist damit gelegt.

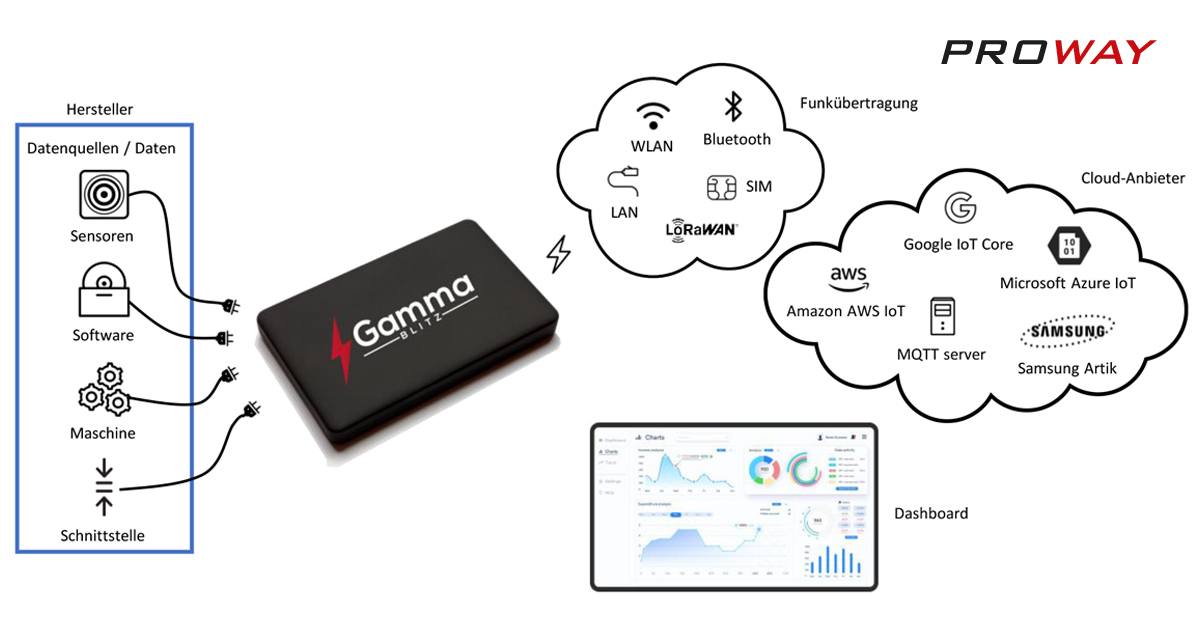

Protokoll- & Datenbrücke Gamma-Blitz

Protokoll- & Datenbrücke Gamma-Blitz

Entdecken Sie die Zukunft der Maschinensteuerung und Überwachung mit dem Gamma-Blitz.

Unsere wegweisende Lösung eröffnet Ihnen umfassende Einblicke und Kontrolle über Ihre Maschinen, Anlagen, Geräte und Anwendungen. Wichtige Parameter wie z.B. Geschwindigkeit, Druck, Temperatur und Vibrationen können Sie in Echtzeit erfassen und auswerten.

Durch eine nahtlose Funkübertragung werden die erfassten Daten in ein einheitliches Format umgewandelt. Im Dashboard werden die Daten visualisiert und geben Ihnen zeitgleich tiefe Einblicke in Ihre Maschinen, Anlagen, Geräte und Anwendungen.

Mit dem Gamma-Blitz haben Sie nun die Möglichkeit, Ihre Betriebsabläufe zu optimieren, die Effizienz zu steigern und die Leistung Ihrer Maschinen zu maximieren. Erfassen Sie präzise Daten, analysieren Sie Trends und nutzen Sie Warnmeldungen, um Ausfallzeiten auf ein Minimum zu reduzieren und Ihren Betrieb effizient zu planen.

Unabhängig von Ihrer Branche – ob im Maschinenbau, in der Fertigung, in der Logistik oder bei der Energieversorgung – der Gamma-Blitz ermöglicht Ihnen, Ihre Maschinen, Anlagen, Geräte und Anwendungen zu überwachen und zu steuern.

Erkunden Sie jetzt unseren Gamma-Blitz und erleben Sie, wie einfach es ist, Maschinen und Geräte zu verbinden, Daten zu sammeln und umfassende Analysen durchzuführen.

Erfahren Sie mehr über den Gamma-Blitz und seine umfangreichen Funktionen: Gamma-Blitz

Proway Nachhaltigkeit | CO²

Unsere Nachhaltigkeit | CO²

Proway steht für ökonomische und ökologische Nachhaltigkeit entlang der gesamten Lieferkette. Wir verfolgen das Ziel, unseren jetzigen und zukünftigen Kunden schon heute, aber auch morgen, Lösungen anzubieten, mit denen sie wachsen und mit denen sie sich auch weiterentwickeln können. Eben über den Standard hinaus.

Mit dem Erreichen unserer Ziele zur Reduktion des CO²-Ausstoßes möchten wir der globalen, ökologischen Verantwortung nachkommen und ein Vorbild für weitere ambitionierte Unternehmen sein.

Unsere Ziele

– Entwicklung von Software, die weniger Rechenleistung benötigt und dadurch den Energieverbrauch senkt.

– Schaffung der Produktlösung und Middleware Gamma zur effektiven und nachhaltigen Steuerung von Prozessen, Maschinen und Geräten.

– Entwicklung der Produktlösung Gamma-Zauberwürfel zur Koordination und effizienten Steuerung von 100.000 Sensoren. Auf diese Weise kann der Energieverbrauch signifikant gesenkt werden.

– Programmierung unserer Warehouse Management Software Proway Business World, um Betriebsabläufe in der Lager- und Logistikbranche effizient und dynamisch zu gestalten. Dadurch werden Ressourcen nicht nur im Energiebereich, sondern auch im Zeit- und Personalmanagement vorausschauend und nachhaltig eingesetzt.

Unsere Ziele stimmen mit europäisch anerkannten Standards überein und unterstützen das Pariser Abkommen von Dezember 2015 hinsichtlich der Beschränkung des Anstiegs der weltweiten Durchschnittstemperatur, der Senkung der Emissionen und Anpassung an den Klimawandel, sowie der Lenkung von Finanzmitteln im Einklang mit den Klimaschutzzielen.

Neben der intensiven Auseinandersetzung mit den Möglichkeiten der Reduktion des eigenen CO2-Ausstoßes beschäftigen wir uns bei Proway damit, wie sie ihre Energieeffizienz maximieren, eine Verbesserung des Ökosystems und der Biodiversität vorantreiben, sowie zur Artenvielfalt, Landnutzung und dem Tierschutz beitragen kann.

Erfahren Sie mehr über Proway zu den Themen Nachhaltigkeit, Philosophie, Partnerschaften & Zertifizierungen, Historie und unseren Proway-Zukunftswald unter Über Proway

Proway Business World: Value Added Services

Value Added Services

Das Durchführen von Sondertätigkeiten und Zusatzhandling – sogenannten Value Added Services (VAS) – ist in der Logistik das „neue Normal“.

Immer häufiger fällt es in den Verantwortungsbereich der Logistik zusätzlich Tätigkeiten im Rahmen des Warenhandlings durchzuführen und damit die verschiedensten Wünsche der Kunden zu erfüllen. Insbesondere gilt dies für Logistikdienstleister (3PL), die in ihren Logistikzentren zeitgleich die Warenabwicklung für mehrere Auftraggeber übernehmen.

Die Ursachen, Zeitpunkte und Häufigkeiten für die Durchführung von Value Added Services sind mannigfaltig. Beispielsweise kann es im Wareneingang erforderlich sein, die Artikel eines speziellen Lieferanten immer auf Sicherheitsbehälter zu verteilen und anschließend neu zu palettieren. Alternativ könnte eine Treueaktion die Ursache sein, bei gewissen Kunden zusätzliche Kataloge oder Dokumente in den Paketen beizulegen. Möglicherweise kann ihr Kunde im E-Commerce eine Geschenkverpackung für gewisse Artikel zubuchen, was zusätzliche Aktivitäten in der Auftragsbearbeitung erforderlich macht.

Entsprechend ist eine korrekte Zuordnung und Ausführung der relevanten Value Added Services eine wichtige Aufgabe moderner Lagerverwaltungssysteme. Selbstverständlich schließt dies auch eine vollständige Protokollierung mit ein, um Transparenz zu allen VAS-Vorgängen zu schaffen.

Wir von Proway kennen das breite Anforderungsspektrum, welches die Durchführung von Value Added Services mit sich bringt. Unsere Proway Business World (PBW) bietet daher bereits diverse Lösungen für ihre VAS-Herausforderungen. Und sollte der PBW-Standard ihre speziellen Sondertätigkeiten nicht abdecken, erarbeiten wir gemeinsam ein optimales Erweiterungskonzept.

Erfahren Sie mehr unter: Warehouse Management System Proway Business World

Frohe Ostern

Frohe Ostern!

Wir wünschen Ihnen und Ihrer Familie ein frohes Fest und genießen Sie die Frühlingszeit.

Vielen Dank für Ihre Treue und das Vertrauen in Proway.

Development in Germany: Seit 23 Jahren als zuverlässiger Partner an Ihrer Seite.

Development in Germany: Seit 23 Jahren als zuverlässiger Partner an Ihrer Seite.

Wir bedanken uns bei allen Mitarbeitern, Kunden und Partnern für 23 schöne und erfolgreiche Jahre.

Mit den zukunftsrelevanten IT-Dienstleistungen und Produktlösungen – entwickelt in Deutschland – konnte sich die Proway gut am Markt positionieren und etablieren und verkörpert Innovativität und Qualität.

Die Proway zeichnet sich stets durch ihre Zuverlässigkeit und ihre Positionierung am Puls der Zeit aus und wird Sie auch in Zukunft weiterhin als starker Partner begleiten. Wir setzen unsere Strategie fort und verfolgen Trends und Technologien in unserer Branche, um Ihnen weiterhin innovative Lösungen bieten zu können.

Wir freuen uns auf die Zukunft mit Ihnen und unseren Mitarbeitern.

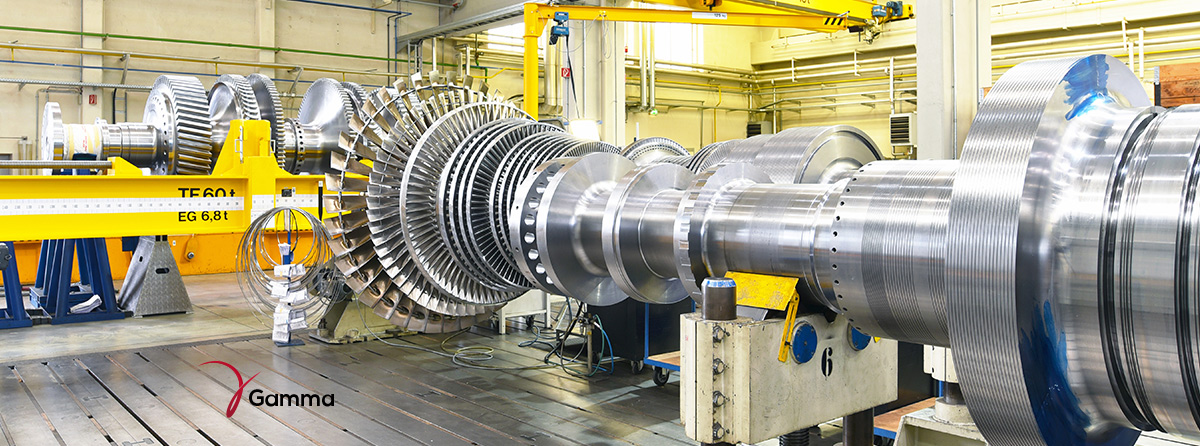

Gamma VI: Maschinenbau und Automatisierung

Gamma VI: Maschinenbau und Automatisierung

Moderne Maschinen und Fertigungsanlagen werden immer komplexer. Der Konkurrenzdruck wächst stetig. Der Markt verlangt nach modernen, leistungsfähigen Maschinen mit zeitgemäßen Mensch-Maschine-Interfaces – aber natürlich bei geringeren Kosten.

Gamma VI eröffnet dem Maschinenbauer den Zugang zur Embedded-Hardware, die gerade bei großen Stückzahlen zu einer drastischen Kostenreduktion führt.

Zum Beispiel können mit modularen Open-Source-I/O-Konzepten Prototypen für Steuerungen aus vorgefertigten Modulen einfach zusammengesteckt werden. Für die spätere Serienfertigung werden diese dann so redesignt, dass die Fertigung vereinfacht wird. Die Verkabelung der Maschine kann wie im Fahrzeugbau über Kabelbäume geschehen. Durch die Kostenreduktion amortisiert sich die Umstellung in kürzester Zeit.

Durch die Vielzahl der Möglichkeiten von Gamma VI steht den Entwicklungsabteilungen der Kunden eine exakt passende Plattform zur Verfügung, die auf die bereits vorhandenen Kerntechnologien eingeht. Damit holen wir die Entwickler exakt bei ihren Fähigkeiten ab und versuchen einen optimalen Entwicklungsprozess zu etablieren.

Lesen Sie mehr unter Gamma VI: Maschinenbau und Automatisierung

ERP-Services: Schnittstellenexpertise

ERP-Services: Schnittstellenexpertise

Als Lagerverwaltungssystem ist es die zentrale Aufgabe von Proway Business World (PBW) die Abläufe innerhalb Ihres Lagers zu koordinieren, kontrollieren und optimieren.

Allerdings ist es für effiziente Prozesse in Ihrem Unternehmen wichtig, dass die Logistik nicht isoliert arbeitet, sondern ganzheitlich eingebunden ist. Dazu wird eine Schnittstelle zwischen Lagerverwaltungs- und ERP-System eingerichtet und alle relevanten Daten und Informationen ausgetauscht.

PBW bietet in seinen ERP-Services verschiedenste technologische Möglichkeiten für solche Schnittstellen. Neben klassischen Datenbankverbindungen (bspw. ODBC, JDBC), Dateiaustausch (bspw. SFTP) sind Anbindungen über Web- und Microservices (bspw. REST oder SOAP) möglich. In jeder Variante können beliebige Dateiformate (bspw. Flatfile, CSV, XML, JSON, IDOC) eingelesen werden. Das zugehörige Mapping der Inhalte erfolgt passend zu Ihren Anforderungen.

Eine optimale Kommunikation zwischen PBW und Ihrem ERP-System ist damit gesichert.

Erfahren Sie mehr unter: Anbindung externer Systeme

Sensoren im Proway-Zukunftswald

Sensoren im Proway-Zukunftswald

In ein paar Jahren wird unser Proway-Zukunftswald in einen Park umgewandelt. Um die 15 verschieden gepflanzten Baumkulturen wie z. B. Lebkuchen-, Mammut- und Tulpenbäume neben Eichen- und Buchen richtig zu pflegen und zu schützen, haben wir unsere Bäume mit Sensoren ausgestattet.

In Sturm-, Hitze- oder Dürrezeiten können gezielt frühzeitig Maßnahmen ergriffen werden. Im Wurzelbereich der Bäume können Sensoren zur Bodenfeuchtigkeitsmessung eingesetzt werden, um so individuell reagieren zu können, ob und wann z. B. auch Jungbäume Wasser benötigen. Besonders in den ersten Jahren ist es wichtig, die Bäume stetig zu beobachten, denn diese leiden häufig unter der zunehmenden Trockenheit und Hitze.

Bekommen unsere Bäume ausreichend Wasser und Licht? Benötigen Sie Düngemittel und mit welchem Düngegehalt? Wie hoch ist der pH-Wert des Substrats? Und müssen Sie geschützt werden bei eisigen Temperaturen?

Auch können anhand der Datenauswertung weitere Rückschlüsse geschlossen werden, wie z.B. welcher unserer gepflanzten Bäume z. B. besonders widerstandsfähig bei Hitze/Kälte ist.

Mit den Sensoren tracken und analysieren wir die Gesundheit unserer Bäume 365 Tage im Jahr.

Vorteile von Sensoren im Proway-Zukunftswald:

– Optimale Wasserzufuhr der Baumkulturen

– Reduzierung der benötigten Wassermenge (Keine pauschale Bewässerung)

– Vorbeugung von Krankheiten und Schädlingsbefall

– Überwachung des Wachstums und Zustand der Bäume:

• Erster Blattaustrieb

• Boden-, Luft- und Blatttemperatur

• Wachstum

• Trockenstress

• Saftfluss (Erfassung und Messung des Wassertransportes im Stamm)

• Bodenfeuchte

• Stammzuwachses / Stammumfang (Messung über Dendrometer)

• Standsicherheit eines Baumes (Ermittlung durch Windreaktionsmessung)

Erfahren Sie mehr unter: https://www.proway.de/innovationen/ sowie unter www.proway.de/gamma-zauberwuerfel

Prowaynachten

Wir wünschen Ihnen und Ihrer Familie besinnliche Feiertage, verbunden mit Gesundheit, Glück und beruflichem Erfolg für das Jahr 2023.

Viele Grüße

Ihr Proway-Team

Innovation gemeinsam schaffen, nutzen und fördern. Netzwerk Smart Production

Innovation gemeinsam schaffen, nutzen und fördern.

Netzwerk Smart Production

Die Proway GmbH geht den nächsten Schritt in Richtung Partnerschaft und findet den Weg zu Smart Production e.V. (Plattform zur Digitalisierung der Produktion) in Mannheim und stärkt zum einen die Smart Production Community und künftig auch die Metropolregion-Rhein-Neckar (MRN).

Mit den Proway Kernthemen rund um Industrie 4.0, Digitalisierung, IIoT, sind wir branchenübergreifend mit unseren Produktlösungen Proway Business World (Warehouse Management), Gamma VI (IIoT-Kommunikationsplattform), dem Gamma-Zauberwürfel (Sensorbox) sowie CS/6 (Business Management Software) Ihr IT-Konzept- und Lösungs-Partner.

Mit dem Gamma-Zauberwürfel tauchen wir in die Welt der Smarten-Lösungen ein. Fokus hier sind die Bereiche Smart Production, Smart Factory, Smart Farming und Smart City mit einer hohen Bandbreite an Standard-Konnektoren sowie Funkverbindungen.

Die Basis hierzu wurde vor über 20 Jahren in der Luft- und Raumfahrttechnik gelegt. Diese Erfahrungen stellen wir nun der Industrie, ob Enterprise- oder KMU-Unternehmen zur Verfügung.

Vielen Dank an Herrn Bley und Team, der die Proway als eine sehr gute Ergänzung im Bereich Smart Production e.V. erkannte und die Aufnahme ermöglichte.

Wir freuen uns sehr auf die Partnerschaft, dass Netzwerken und sind jetzt schon auf die kommenden Aktivitäten, den intensiven Austausch mit den Mitgliedern, der Stadt Mannheim und der MRN gespannt.

Proway Partner- und Mitgliedschaften: https://www.proway.de/partnerschaften-zertifizierungen/

Sensorbox Gamma-Zauberwürfel in einer Smart City

1.000 Sensoren in Echtzeit - 100.000 Sensoren in der Steuerung und Verwaltung

Mit dem Gamma-Zauberwürfel können über 1.000 Sensoren gleichzeitig – 100.000 Sensoren in der Steuerung und Verwaltung – angebunden und in Echtzeit abgefragt werden.

In einer Smart City werden z. B. Abwassersysteme mit Sensoren ausgestattet, um Daten wie Wassermenge, Druck, Fließgeschwindigkeit und Temperatur permanent zu überwachen. Auch Kanäle oder Schächte können überwacht werden, die mit Wasser und Gasen gefüllt sind. Die Sensoren übermitteln die Werte an den Gamma-Zauberwürfel, die direkt ausgewertet werden können.

Auch im Bereich der Überwachung und Steuerung freier Parkplätze können Parksensoren mit digitaler Anzeige angebracht werden. Ebenso die Überwachung von Korrosions- oder Feuchtigkeitsschäden bei Straßen- und Brücken im Straßenbelag, Beton und in Stahlkonstruktionen. Die Möglichkeiten in verschiedenen Bereichen sind vielseitig.

Je nach Ausbaustufe können über 1.000 Sensoren gleichzeitig verwaltet und gesteuert werden. Es können mehrere Gamma-Zauberwürfel untereinander vernetzt werden – beispielsweise aus einzelnen Stadtteilen.

Erfahren Sie mehr über unseren Gamma-Zauberwürfel in unseren Filmen und auf unserer Website unter Gamma-Zauberwürfel – Smart City

Gamma VI - Maschinenbau

Middleware für Maschinenbau und Automatisierung

Unsere vielen Ideen entstehen aus den Anforderungen unserer Kunden. Aus den Anforderungen werden Projekte. Aus den Projekten werden Prototypen und Prototypen werden zu Ergebnissen unserer Produkte. Durch Gamma VI können Sie die digitalisierte Produktion. „Cloud“, (IoT)“, Ihre Maschinen jederzeit ohne Programmiermethoden umstellen.

Eine Technologie einsetzen, die Ihre Maschinenteile selbstständig vernetzt und so eine Durchgängigkeit vom Sensor bis zum austauschbaren Produktionsnetzwerk ermöglicht? Eine Plattform, die nahezu jede embedded Hardware unterstützt, langfristig austauschbar ist und nebenbei noch beträchtliche Kosten spart?

Mit unserer Middleware Gamma VI bieten wir Lösungen für die Umwälzungen, die durch die Digitalisierung entstehen. Die Middleware wird zu einer einheitlichen Laufzeitplattform mit allen erforderlichen Schnittstellen zur Hardware, dem Internet der Dinge und die für den Anwender passenden Entwicklungsumgebungen. Dies erlaubt den Einsatz nahezu beliebiger embedded-Hardware.

Wollen Sie mehr erfahren? Kontaktieren Sie uns gerne. Weitere Informationen finden Sie unter Gamma: Middleware für Maschinenbau und Automatisierung

IT-Testsysteme

Testsysteme

Ob Luftfahrt, Automotive, Rail oder Automatisierung – ohne gründlichen Test geht heutzutage nichts mehr. Wir unterstützen Sie bei der Entwicklung, als auch beim Umgebungs- und Fertigungstest.

Testsysteme sind in vielen Branchen unverzichtbar

Die Testbranche befindet sich im Umbruch. Waren Testsysteme früher nur zur Endkontrolle und Qualitätssicherung in der Fertigung im Einsatz, beginnt heute das Produktdesign mehr und mehr im Rechner, wo modernste Simulationen auf klassische Verfahren aus der Testbranche zurückgreifen. So kann lange bevor ein Prototyp als Hardware-in-the-loop (HIL) in einem Prüfbett liegt, bereits virtuell mit Model- und Software-in-the-loop (MIL / SIL) gearbeitet werden. Durch diese Veränderung wird der durchgehende Test zum ständigen Begleiter der Produktentwicklung.

Stresstests unter Echtzeitbedingungen im Automotive

Gamma wird nicht nur im Aerospace-Testing, sondern auch in anderen Branchen -wie z. B. Automotive-, eingesetzt und dabei hauptsächlich in „Hardware In The Loop Testsystemen“. Meistens ist das Ziel, Embedded Systems unter Echtzeitbedingungen speziellen Stresstests zu unterziehen.

Erfahren Sie mehr unter https://www.proway.de/testsysteme/

Inventur

Same procedure as every year, Mr. Wirtschaftsprüfer

In jedem Lager müssen einmal innerhalb eines Geschäftsjahres Bestände physisch überprüft und mit den Buchwerten abgeglichen werden. Dadurch steht meist am Jahresende die Inventur an. Der Gedanke an die Inventur löst bei vielen Warehousemanagern Unbehagen aus.

Proway Business World (PBW) unterstützt Sie bei jeder Art der Inventur durch standardisierte und intuitive Prozesse, um Kosten und Aufwände so gering wie möglich zu halten.

Üblicherweise erfolgt die Inventuraufnahme zum Bilanzstichtag. Diese sogenannte Stichtagsinventur wird vollumfänglich in Proway Business World abgebildet. Dabei erfolgt für die Inventur eine Sperrung des kompletten Lagerbestandes, da in dieser Zeit keinerlei Warenbewegungen stattfinden dürfen. Es besteht die Möglichkeit die Inventur nur für belegte Lagerplätze, nur für Leerplätze oder für alle Lagerplätze anzulegen, so dass sichergestellt ist, das alle inventurrelevanten Artikel und Bestände geprüft sind.

Die notwendigen Zähllisten können entweder ausgedruckt, oder auf ein mobiles Datenerfassungsgerät (MDE) und Tablet ausgegeben werden. Nach Ende der Erstzählung kann man die Differenzen prüfen und eine Zweit- bzw. Drittzählung anstoßen. Den Inventurfortschritt kann hierbei lückenlos überwacht werden.

Um die Zählaufwände besser auf das komplette Jahr zu verteilen, bietet PBW die permanente Inventur mit an. Dadurch ist sichergestellt, dass der komplette Lagerbestand einmal innerhalb eines Geschäftsjahres bereits vor dem Stichtag gezählt wird. Dies bietet sich insbesondere für Automatik-Lagerbereiche, wie z.B. Shuttlelager, Hochregallager mit Regalbediengeräten, Tablare, AKl‘s, etc. an.

Natürlich unterstützt PBW unterschiedliche Inventurarten für einzelne Lagerbereiche.

Nach Ende der Inventur kann man Inventurberichte anstoßen, in denen die wichtigen Informationen wie beispielsweise Soll-Ist-Werte, aber auch Differenzen in Anzahl und Prozent ausgewiesen werden. Über diese Berichte erfolgen die Bestandskorrekturen mit dem ERP-System. Jedoch können diese auch direkt versendet und archiviert werden.

Auf diesem Wege ermöglicht Ihnen PBW mit effizienten Lösungen und ohne Stress am Stichtag zu sagen: Same procedure as every year, Mr. Wirtschaftsprüfer.

Weitere Informationen dazu finden Sie unter www.proway.de

Aerospace & Defence Dienstleistungen

Aerospace & Defence Dienstleistungen

Der Business Case Software Engineering und Services im Umfeld der Vermeidung von Personenschäden ist hoch aktuell, denn der Imageschaden bei einen Schadensereignis sind in der Regel gravierender als die entsprechenden Entwicklungskosten zur Vermeidung von Schäden.

Proway bietet Ansätze und Lösungen, die sowohl für Sicherheit als auch Innnovation sorgen, was sich dadurch zeigt, dass viele Kunden aus sicherheitskritischen Bereichen ein langjähriges Vertrauen in die Kompetenz Engineering Services und der Funktion der Produkte von Proway haben.

Systemtechnische Dienstleistungen sind ein weiterer wichtiger Business Case der Proway. Bei Proway liegt seit Jahren der Fokus auf den sicherheitskritischen Bereichen wie Umwelt/Gefahrstoffe, Energieversorgung, Luft-/Raumfahrt, Militär und Medizin. Vor allem im Sensorbereich ist bei Proway sehr viel Erfahrung mit sicherheitskritischen Systemen und Komponenten vorhanden. Dabei kommen qualifizierte System-, Elektronik, und Maschinenbauingenieure von Proway zum Einsatz.

Erfahren Sie mehr unter Aerospace & Defence

Proway-Zukunftwald

Proway Zukunftswald

Technologie bedeutet oftmals der Natur etwas zu nehmen. Wir übernehmen Verantwortung als zukunftsfähiges und nachhaltiges Unternehmen.

Der Abbau von Metallen, die Stromerzeugung durch Kohlekraftwerke und der Straßenbau sind Beispiele, bei der wir der Natur etwas abverlangen, damit unsere Gesellschaft profitiert. Dabei spielt die Technologie eine immer wichtigere Rolle, gerade für Unternehmen, die mit dem globalen Wettbewerb Schritt halten müssen.

Wir haben uns Gedanken gemacht, wie wir Natur und Technologie vereinen können. Der erste Schritt war unser „Umdenken“: Wie schaffen wir es, mit unserer Technologie unserer Natur zu helfen. Das Ergebnis war, dass wir der Natur ein gutes Stück zurückgeben müssen, was wir der Natur bereits entnommen haben. So wurde das Projekt geboren, einen Proway-Zukunftswald anzulegen, um zeigen zu können, dass wir nicht nur von Natur und Technologie sprechen, sondern uns auch aktiv für beide engagieren.

Mit unserem Proway-Wald setzen wir nicht nur ein Zeichen, sondern verändern auch aktiv die Zukunft mit unserem Tun & Denken mittels unserer Gamma-Technologie.

Mehr Informationen finden Sie unter Proway-Zukunftswald

Teamevent Tripsdrill

Teamevent Tripsdrill

Letzten Mittwoch war es endlich so weit: Das lang ersehnte Teamevent vereinte Kollegen aus den Standorten Stuttgart, München und Ulm unter dem Motto “Proway goes Performance”. Der Freizeitpark Tripsdrill war die geeignete Kulisse, um unserem dynamischen Team in Sachen Performance und Sportlichkeit, gerecht zu werden.

Die Achterbahn „Karacho“ und „Hals-über-Kopf“ standen Pate für Technologie, Know-how und Geschwindigkeit – Eigenschaften, die sich in der Proway bspw. in der Softwareentwicklung widerspiegeln.

Aber nicht nur Proway, sondern der einzelne Mitarbeiter standen im Fokus für das Teamevent. Dabei lag das Augenmerk darauf, einen erlebnisreichen Tag voller Spaß und Action gemeinsam zu verbringen.

Neben einzigartigen Attraktionen rundete eine Technikführung mit Blick hinter die Kulissen den Tag ab. Detailverliebte kamen auch hier auf ihre Kosten.

Rundum war es ein erfolgreicher und schöner Tag, von dem wir noch lange gemeinsam zehren können. Denn Proway geht auf Performance – auch bei ihren Teamevents.

11. Firmencup MZRN.

11. Firmencup MZRN.

Proway freut sich, beim 11. Firmen-Golf-Cup Rhein-Neckar des Vereins Zukunft Metropolregion Rhein-Neckar e. V. dabei gewesen zu sein.

Sich gemeinsam in der Metropolregion zu engagieren und das Charity-Turnier zu unterstützen, ist uns eine Ehre. Vielen Dank an Kirsten Korte und sein Team, die es wieder einmal mehr als genial organisiert haben. Das traumhafte Wetter, der Platz im Golfclub St. Leon-Rot in perfektem Zustand und die Flightpartner von Heidelberg-IT waren eine gelungene Mischung!

Vielen Dank in Vorfreude auf das nächste Jahr!

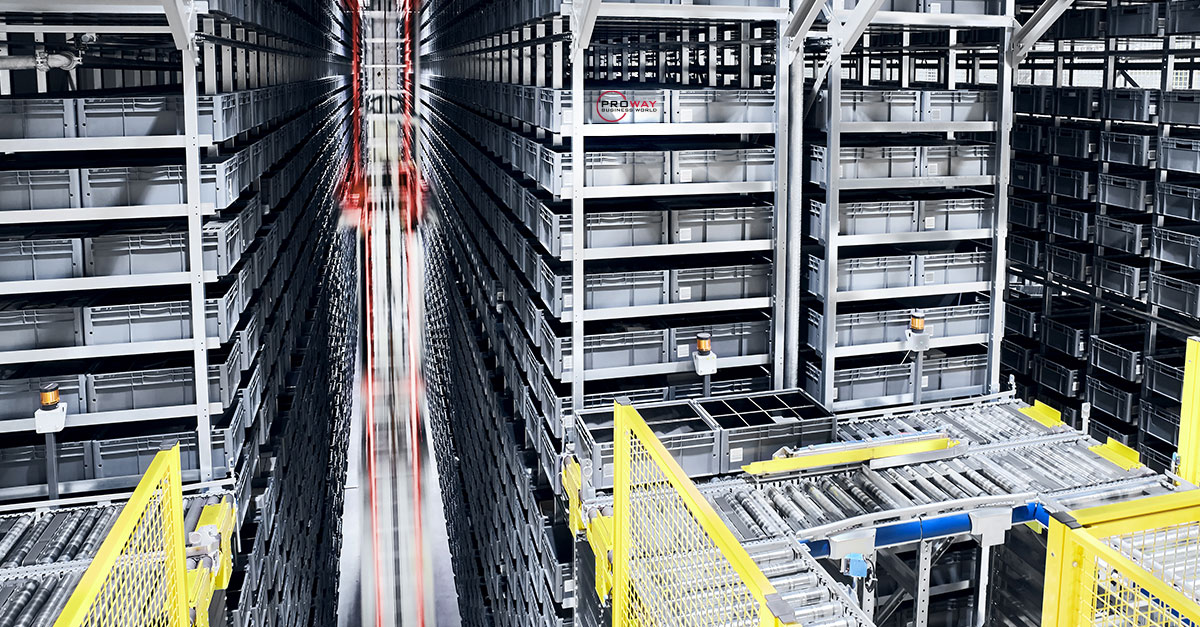

Automation Services

Automation Services: AKL & Shuttle-Lager

Kennen Sie den Unterschied zwischen einem automatischen Kleinteilelager (kurz AKL) und einem Shuttle-Lager?

Häufig werden diese beiden Begriffe bei Gesprächen über die automatisierte Lagerung von kleinen Artikeln in Behältern als Synonym verwendet.

Trotz vieler Parallelen zwischen beiden Lagertechniken erfolgt die Versorgung von Behältern innerhalb der Gänge jeweils unterschiedlich.

In einem AKL kommen üblicherweise Regalbediengeräte (kurz RBGs) zum Einsatz. Diese transportieren die Behälter von einem Übergabepunkt an den Zielplatz. Dabei übernimmt das RBG die gesamte horizontale und vertikale Transportstrecke im Gang.

Ein Shuttle-Lager trennt die Aufgaben des horizontalen und vertikalen Transportanteils. Ein Lift befördert die Behälter auf einen Übergabepunkt in der richtigen Ebene. Ein Shuttle-Fahrzeug übernimmt den Behälter und verbringt diesen horizontal an seinen Zielplatz.

Je nach Hersteller gibt es zudem verschiedene Umsetzungsvarianten dieser beiden Konzepte. Für ein Lagerverwaltungssystem bedeuten diese Unterschiede zeitgleich auch abweichende Anforderungen an die Materialflusssteuerung:

• Was ist der optimale Lagerplatz eines Behälters?

• Wie stelle ich eine gleichmäßige Auslastung sicher und schaffe zeitgleich durch Gassen- und Ebenenverteilungen der Artikel eine Ausfallsicherheit?

• Wie berücksichtige ich unterteilte Behälter mit verschiedenen Artikeln?

• Welche Notfallstrategien bestehen bei Ausfall der jeweiligen technischen Komponenten?

• Welche Komponenten der SPS sind anzusteuern?

• Wie erfolgt die Kommunikation mit der SPS?

Die Funktionalität unserer Produktlösung Proway Business World (PBW) trägt der Vielzahl an Möglichkeiten Rechnung und bieten Lösungen für alle Fragen – vollkommen flexibel. Jede Variante von AKL oder Shuttle-Lager kann herstellerunabhängig durch PBW angebunden, gesteuert und optimal verwaltet werden.

Lesen Sie mehr: Automatik- und Fördertechnik

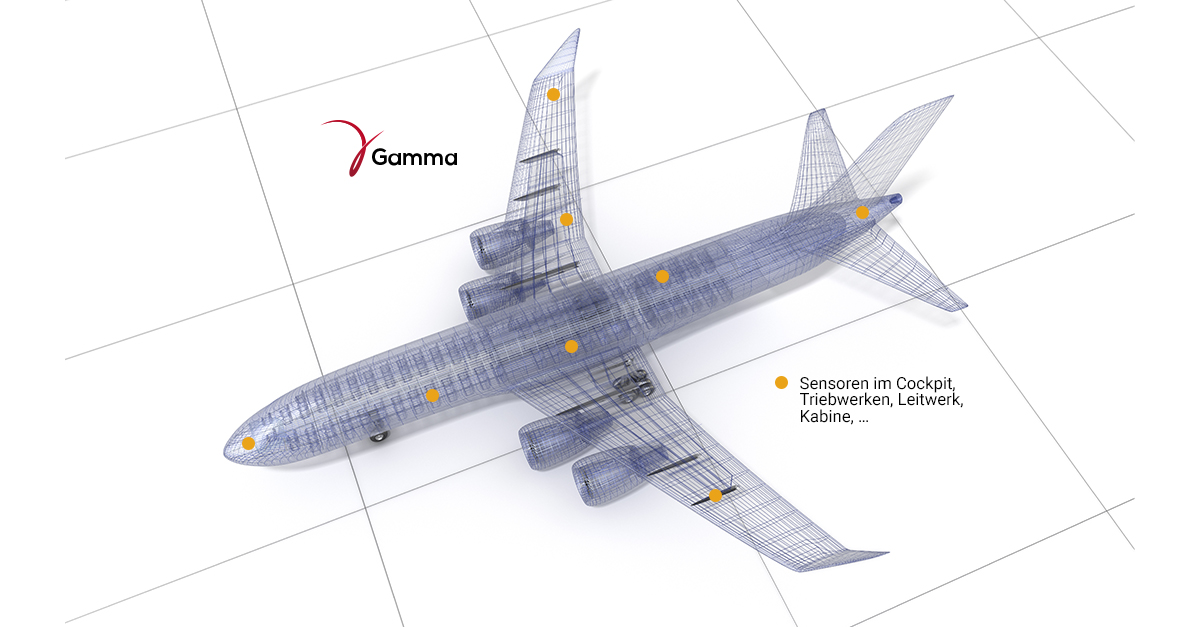

1.000 Sensoren-Zustände in Echtzeit verwalten

1.000 Sensoren-Zustände in Echtzeit verwalten

Um in der Luft- und Raumfahrt robuste und zuverlässigere Systeme zu gewährleisten, wurde vor über 20 Jahren mit der Entwicklung der Gamma-Software begonnen. Daraus entstand die erste Version Gamma, mit der man Flugzeugteststände und Turbinen rund um die Uhr auf deren Belastbarkeit und Zuverlässigkeit simulieren und testen konnte. Seitdem wurde Gamma ständig weiterentwickelt, sodass heute unter anderem in der sechsten Generation Produkte in Luft- und Raumfahrzeugen in Langzeit-Stresstests getestet und simuliert werden können.

Das Herzstück der aktuellen Version Gamma VI sind das Datenmodell und das Messaging. Damit lassen sich über 1.000 Zustände und Funktionen und vielfältigen Busprotokollen viele Aktoren und Sensoren gleichzeitig in Echtzeit abfragen, steuern und verwalten. Typische Einsatzgebiete sind Stresstests in den Bereichen Elektronik und Höhenleitwerken, Turbinen und Power Units oder die Mechanik von Flügelkomponenten.

Dies ist vergleichbar mit 1.000 Angestellten, die allesamt in den unterschiedlichsten Funktionen, wie der Steuerung des Höhenleitwerks oder der Regelung der Turbinenleistung am Flugzeug, gleichzeitig zusammenarbeiten.

Diese Leistungsfähigkeit wurde bisher von keiner Software erreicht. Auf dieser Basis entstand der Gamma-Zauberwürfel. Dieser kann über 1.000 Sensoren-Zustände, wie Hitze, Feuchtigkeit, Staub usw., gleichzeitig und in Echtzeit verwalten. Da es am Markt inzwischen tausende von Sensoren gibt, die Gamma verwalten und steuern kann, sind dem Zauberwürfel keine Grenzen gesetzt. Vom privaten Netzwerk, über Produktionen bis hin zu ganzen Städten können mit dem Gamma-Zauberwürfel all diese Sensoren verwaltet und gesteuert werden. Die Technologie des Gamma-Zauberwürfels basiert auf der Erfahrung von über 30 Jahren in Sachen Qualität und Zuverlässigkeit für die Luft- und Raumfahrt.

Erfahren Sie mehr über unseren Gamma-Zauberwürfel in unserem Film oder auf unserer Internetseite.

Multifunktions- E/A-Karten & E/A-Karten mit hoher Dichte.

Multifunktions- E/A-Karten & E/A-Karten mit hoher Dichte.

Im Industriellen Standard kommen Multifunktions-E/A-Boards in OpenVPX-, cPCI-, VME- und PCI/PCIe-Formfaktoren mit 3 oder 6 HE zum Einsatz.

In der Kombination mit unseren intelligenten Funktionsmodulen sind diese in der Lage, eine sehr breite Palette komplexer und zeitkritischer Erkennungs- und Antwortanforderungen für I/O-intensive, unternehmenskritische Anwendungen zu erfüllen. Diese Boards wurden speziell für die anspruchsvollsten Industrie-, Verteidigungs-, als auch Luft- und Raumfahrt-Anwendungen entwickelt und sind mit einem modularen E/A-Ansatz ausgestattet, der die Bereitstellung von COTS-basierten, SWaP-optimierten Lösungen mit hoher Dichte beschleunigt.

NAIs Standard Multifunktions-E/A-Boards können mit bis zu 6 individuellen Funktionsmodulen bestückt werden.

Diese sind digitale E/A – TTL-, CMOS-, diverse Relais-, Thermoelement- und RTD-Messungs-, IEEE 1394 (FireWire)-, diskrete programmierbare IO – Mehrkanal-, LVDT RVDT-Messung und -Simulation-, Digitale IO – Differenzieller Transceiver-, MIL-STD-1553B Datenbus-, CANBus-Kommunikations-, ARINC-Kommunikations-, intelligente ADx Analog zu Digital-, AC-Referenz-, Reluktanz- (VR) und Allzweck-Impulszähler-, Time Triggered Ethernet (TTE)-, Dehnungsmessstreifenmessungs-, serielle Kommunikation-, Ethernet-Switch-, Ethernet-NIC-Schnittstelle -, Chip-Detektor und Fuzz Burn-, SATA-Solid-State-Laufwerk (SSD)-, Synchro-Resolver-Messung und -Simulations-, Digital-zu-Analog- sowie MIL-STD-1760-Kommunikations-Smart-Funktionsmodule.

Zusätzlich bieten wir für besondere Anwendungen Multifunktions- oder Kombinationsfunktions-E/A-Karten mit hoher Dichte in 3HE, 0,8“ Raster / 4TE im OpenVPX™ Standard an.

Als Distributor der Herstellers North Atlantic Industries für Deutschland, Österreich und der Schweiz beraten wir Sie gerne und stehen bei Fragen über Messgeräte, Simulatoren und Multifunktions-I/O-Karten jederzeit zur Verfügung Mehr Infos finden Sie unter:

Mit Gamma in den Wirkbetrieb

Mit Gamma in den Wirkbetrieb

Ohne middlewarebasierte Testsysteme können keine Projekte in der Luft- und Raumfahrt, im Automotive, im Maschinenbau usw. in den Wirkbetrieb gehen.

Mit unseren Testsystemen auf Basis unserer Produktlösung Gamma begleiten wir die Hersteller von der Entwicklungsphase bis zum produktiven Einsatz. Dabei ist Gamma ein Teil der Gesamtstrategie, um einzelne Komponenten in die modulare Laufzeitplattform in Echtzeit einzubinden. Nur so können langfristige Testlandschaften die Entwicklungs- und Produktionsprozesse über Jahrzehnte begleiten.

Unterschiedliche Lieferanten können über die offene Architektur von Gamma eng zusammenarbeiten und erleichtern so jedem einzelnen Anwender und Entwickler das Verständnis der Abhängigkeiten der einzelnen Komponenten eines komplexen Testsystems.

Gamma ist eine offene und serviceorientierte Testplattform für einfache bis hochkomplexe Systeme.

Weitere Informationen inklusive Anwendungsfall finden Sie unter Middlewarebasierte Testsysteme

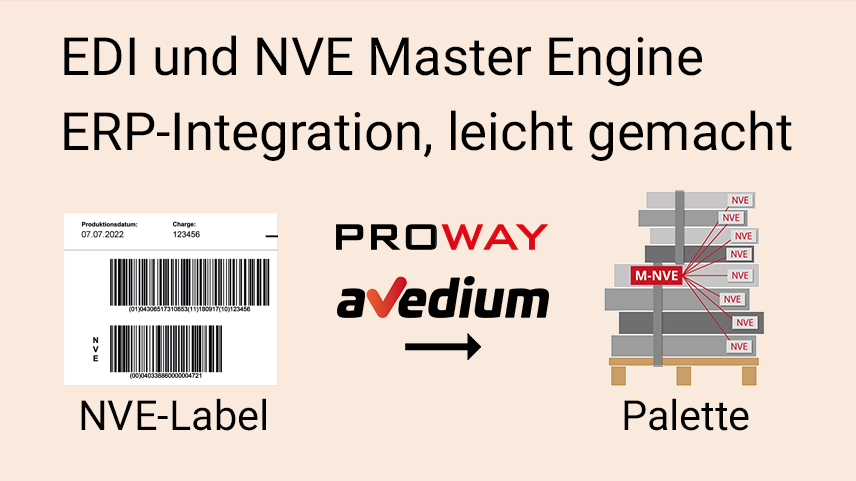

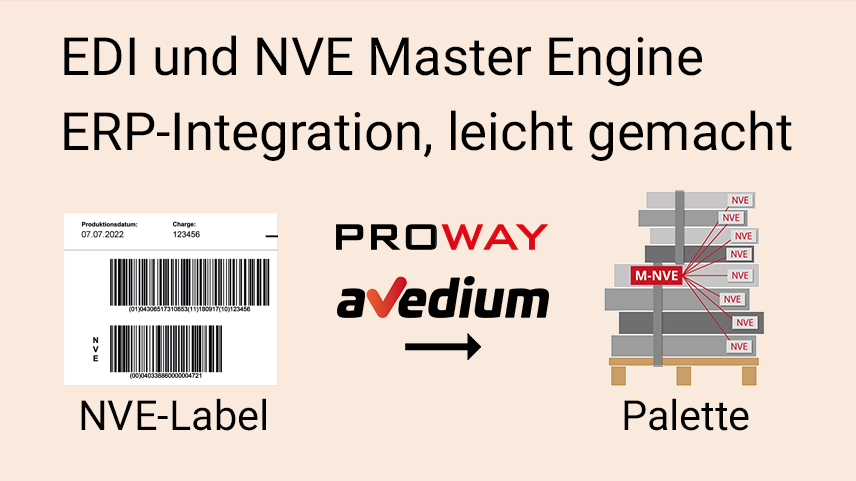

Was ist NVE bzw. SSCC?

Was ist NVE bzw. SSCC?

NVE (SSCC, engl. Serial Shipping Container Code) steht für eine weltweit eindeutige Nummer zur Identifizierung einer Versandeinheit. Die NVE / SSCC ist eine 18-stellige Identifikationsnummer für die Kennzeichnung von z. B. Containern, Paletten oder Kartons.

Die Nummer dient der Verfolgung und Rückverfolgung (Tracking und Tracing) jeglicher Art von Waren über den gesamten Transportweg hinweg. Jede Nummer wird nur einmalig vergeben und kann vollautomatisch ausgelesen werden. Bei der Zusammenführung mehrerer Versandeinheiten, kann eine übergeordnete NVE angelegt werden.

Durch Angabe der NVE / SSCC kann die Sendung lückenlos nachverfolgt werden und im elektronischen Datenaustausch (EDI) als zentraler Schlüssel hinterlegt werden.

Als weltweit standardisierter Code fordern viele Handelsunternehmen den Einsatz dieser Kennzeichnung. Mit der NVE Master Engine können Sie diese Barcodes schnell und einfach erzeugen – mit nur einer Schnittstelle und unterschiedlichen Anbindungsmöglichkeiten.

Zusammen mit dem EDI-Partner Avedium Technologie GmbH wurde das Produkt NVE Master Engine entwickelt.

Erfahren Sie mehr darüber in unserem Workshop: EDI und NVE Master Engine ERP-Integration, leicht gemacht.

Wir freuen uns, Sie zu unserem Webcast am 07.07.2022 um 10.00 Uhr einzuladen und kennen zu lernen. Melden Sie sich an unter: LinkedIn

Integration der Proway-Produktlösung "NVE Master Engine"

Integration der Proway-Produktlösung "NVE Master Engine" in die avEDIum EDI Plattform

NVE steht für eine weltweit eindeutige Nummer zur Identifizierung von Versandeinheiten. Zusammen mit dem EDI-Partner Avedium Technologie GmbH wurde das Produkt NVE Master Engine entwickelt.

Aufgrund der umfangreichen Erfahrung im Bereich Logistik und unserer Warehouse Management Lösung „Proway Business World“ garantieren wir eine sichere und zuverlässige EDI-Lösung auf Basis der Avedium-Plattform.

Mit der NVE Master Engine ist es Proway gelungen, ERP-Systeme aus dem Mittelstand und im Enterprise-Umfeld, sehr einfach und schnell zu integrieren.

Unser Fokus galt in erster Linie der Anbindung von Bestandskunden aus den ERP-Systemen SAP Business One, Sage, Infosense und M-Soft. Mit der NVE Master Engine haben wir nun die Möglichkeit geschaffen, NVE-Labels und EDI-Lieferavis direkt aus dem ERP-System zu erstellen. Das EDI-Lieferavis wird auf dem elektronisch standardisierten DESAV-Format ausgegeben.

"International students meet regional companies - Make it in Ulm"

"International students meet regional companies - Make it in Ulm"

Wir von Proway sind heute auf der “International students meet regional companies – Make it in Ulm” vertreten.

Wir bieten interessierten Studenten (m/w/d) die Möglichkeit im Bereich der Entwicklung unserer Middleware Gamma VI sich frei zu entfalten und praktische Erfahrungen zu sammeln: Praktika | Werkstudententätigkeiten | Bachelor- und Masterarbeiten

Aufgaben & Schwerpunkte:

Entwicklung Produktlösung Gamma VI

Betreuung und ansprechende Darstellung unserer Middleware

Weitere Informationen finden Sie unter: Bachelor- und Masterarbeiten

Neue Partnerschaft mit der Avedium Technologie GmbH.

Neue Partnerschaft mit der Avedium Technologie GmbH.

Die Avedium Technologie GmbH wird strategischer Partner im Bereich EDI. Die Proway stellt aus dem Bereich PBW der eigenen Warehousemanagement-Lösung (WMS) Ihre NVE / SSCC, in Form der NVE Master Engine der Avedium EDI-Lösung als integrierte Funktionserweiterung zur Verfügung.

Workshop: EDI und NVE Master Engine ERP-Integration, leicht gemacht.

Wir freuen uns, Sie zu unserem Webcast am 07.07.2022 um 10.00 Uhr einzuladen und kennen zu lernen. Melden Sie sich an unter: LinkedIn

1. Forschungsnetzwerk-Treffen "Neues Kreislaufsystem 2+12"

1. Forschungsnetzwerk-Treffen "Neues Kreislaufsystem 2+12"

1. Forschungsnetzwerk- Treffen “Neues Kreislaufsystem 2+12” am Kompetenzzentrum Obstbau Bodensee (KOB)

Es wurden die Themen Vermeidung von Lebensmittelverschwendung, Zero Waste Factory und natürlich der Startschuss für das neue Forschungsnetzwerk “Neues Kreislaufsystem 2+12” gegeben.

Alle Beteiligten, unterstützen die o.g. Themen und positionieren sich in Ihrem Fokus. So auch die Proway GmbH, indem wir unsere Lösung, Gamma VI, zur Verbesserung der Digitalisierung und der Nachhaltigkeit bereitstellen. Durch unsere Kommunikationsplattform Gamma VI, werden an der Maschine erzeugten Daten, direkt aufbereitet und zur weiteren Verarbeitung und Analyse, in Sachen Skalierbarkeit an alle Subsysteme weitergeleitet.

Dadurch entsteht eine tiefe Integration aller vorhandenen Systeme.

Neue Logistik-Lösungen für ein dynamisches Wachstum im Bereich E-Commerce und Direktlieferung.

Neue Logistik-Lösungen für ein dynamisches Wachstum im Bereich E-Commerce und Direktlieferung.

Neue Logistik-Lösungen für ein dynamisches Wachstum im Bereich E-Commerce und Direktlieferung. Dabei spielt hohe Flexibilität mit der passenden Strategie eine entscheidende Rolle.

Großaufträge verringern sich und die Zahl der Aufträge mit wenigen Positionen und kleinen Menge steigen rasant an. Hierzu ein einfaches Beispiel: Wenn Sie im Onlineversand eine elektrische Zahnbürste mit Ersatzköpfen einfach bestellen können, benötigt der Drogeriemarkt um die Ecke hingegen das gesamte Sortiment von elektrischen Zahnbürsten, um am Markt bestehen zu können. Denn die Kunden lieben es, in einem großen Sortiment ihre Wahl für ein Produkt selbst treffen zu können.

Als Konsequenz verändern sich die Anforderungen in den Lagern und Logistikzentren für die Abwicklung der Aufträge. Eine effiziente Strategie für die Kommissionierung der Waren ist notwendig, um die Situation zu handeln, aber auch schnell genug zu sein, um Kosten und Zeit zu sparen. Dabei darf die bestehende Abwicklung zu den vertrauten Großkunden und Händlern nicht darunter leiden.

Das Proway Lagerverwaltungssystem PBW bietet in diesen unterschiedlichen Situationen die erforderliche Flexibilität mittels passender Strategien:

• Auftragsbezogene Kommissionierung

• Multi-Order-Picking

• Negativ-Kommissionierung

• Block-Kommissionierung

• Pick und Pack

Viele dieser Optionen können nach Bedarf und Bedürfnissen für eine optimale Abwicklung kombiniert werden.

Unabhängig von der gewählten Strategie stellt das Warehouse Management System PBW sicher, dass der Kunde immer die korrekte Ware in der passenden Menge nach spezifischen Vorgaben wie zum Beispiel Charge, MHD und viele weiteren Funktionen erhält.

Mehr erfahren unter: Warehouse Management Proway Business World

Robuste Netzteile für selbstständige Geräte.

Robuste Netzteile für selbstständige Geräte.

Robuste Netzteile für selbstständige Geräte wie Flugkörper, U-Boote und fahrerlose Transportfahrzeuge für die Industrie sowie Luft- und Raumfahrt. Die steigende Nachfrage nach robusten Commercial Off-the-Shelf (COTS), modifizierten COTS und kundenspezifischen Netzteilen beflügelte die Entwicklung moderner leistungsfähiger Stromversorger mit großer Bandbreite für viele Einsatzgebiete.

Dies gilt auch für Konfigurationen, die die Anforderungen von VME, cPCI und VPX (VITA 62) erfüllen, sowie alle entsprechenden Umweltstandards für raue Umgebungen, einschließlich MIL-STD-810G, VITA 47 und MIL-STD-901. Die robusten Netzteile unseres Partners North Atlantic Industries verfügen außerdem über integrierte EMI-Filter gemäß MIL-STD-461-Standards.

Diese Netzteile mit hoher Dichte wurden speziell für robuste Verteidigungs-, Industrie- und kommerzielle Anwendungen entwickelt, die unter extremen Bedingungen betrieben werden. Sie bieten erhebliche Kostenvorteile und liefern COTS-Lösungen, die den Einsatz von SWaP-optimierten Systemen in Luft-, Land- und Seesystemen beschleunigen. Zu den verfügbaren Formfaktoren gehören 3U-, 6U-, Brick- und Standalone-Einheiten.

Als Distributor der Herstellers North Atlantic Industries für Deutschland, Österreich und der Schweiz beraten wir Sie gerne und stehen bei Fragen über Messgeräte, Simulatoren und Multifunktions-I/O-Karten jederzeit zur Verfügung Mehr Infos finden Sie unter: North Atlantic Industries

Klare Projektübersicht mit CS/6.

Klare Projektübersicht mit CS/6.

Klare Projektübersicht mit dem ausgereiften Controlling- und Managementsystem CS/6.

Unser Produkt ist eine cloudbasierte Softwarelösung zur Verwaltung von Projekten, Organisation, Office, Recruiting, Technik, Buchhaltung, Vertrieb und Controlling. Proway kann leistungsorientierte Projekte aufbauen, koordinieren & steuern durch Know-how & elektronische Projektsteuerung CS/6. Mitarbeiter werden über ein sehr umfangreiches und ausgefeiltes Rollen- und Rechtemanagement verwaltet.

Die Business Suite CS/6 wird als Projekt-, Ticket- und Zeiterfassungssystem seit 2003 für unsere Kunden ständig weiterentwickelt.

Erfahren Sie mehr unter: CS/6

Wir verbinden Technologie und Maschinen.

Wir verbinden Technologie und Maschinen.

Mittels des Gamma-Zauberwürfels können Daten in nur einer App überwacht werden. Wir verbinden Technologie und Maschinen.

Wäre es nicht toll, wenn Sie Sensoren unterschiedlicher Hersteller verbinden und diese alle in einer App verwalten, steuern und auslesen könnten?

Legen Sie außerdem Wert auf höchste Datensicherheit? Wir von PROWAY bieten Ihnen eine effiziente Lösung, perfekt abgestimmt auf Ihre Bedürfnisse. Direkt vom Feld, von Zuhause oder auch vom Maschinenpark.

Meine Daten

Eigentümer der Maschinen- und Sensordaten ist der Auftraggeber. Weder die Stadt noch ein Industrieunternehmen kann Ihre Daten einsehen, ohne dass diese persönlich weitergegeben werden.

Standortunabhängig

Ortsunabhängige Steuerung und Kontrolle von Daten und Sensoren.

Sicherheit

Überblick behalten, aber im eigenen Netzwerk. Die Daten und Informationen bleiben auf dem PC, Laptop, Tablet oder dem eigenen Server (Applikation)

Keine Cloudlösung

Keine Cloudlösung, nur wenn gewünscht. Abruf über das eigene Netzwerk.

Verschlüsselte Funkverbindung

Sichere Verbindung über Bluetooth, WLAN, LAN, D-Netze und LoRaWAN.

Einfaches Handling

Überwachung ihrer Daten in nur einer App

Erfahren Sie mehr unter: Gamma-Zauberwürfel

Technologie aus Luft- und Raumfahrt.

Technologie aus Luft- und Raumfahrt.

Wenn Technologie aus Luft- und Raumfahrt sämtliche Maschinen verbinden und steuern, dann ist die Middleware Gamma im Einsatz. Wiederkehrende Standardaufgaben von Technikern und Entwicklern werden vollautomisch übernommen.

Stellen Sie sich vor, es gäbe eine Plattform, die Ihren Entwicklern die immer wiederkehrenden Standardaufgaben abnimmt, damit diese sich voll auf Ihre spezifische Anwendung konzentrieren können?

Mit der Produktlösung Gamma VI hat der Entwickler nun die Möglichkeit, Prozessen und Datenanbindungen zu automatisieren. Eine Produktlösung, die Prozesse und Daten innerhalb Ihrer Systeme eigenständig kontrolliert und verwaltet, die Sie schon während der Entwicklung unterstützt und für neue Standards offen bleibt, sodass sie Wartung und Upgrades für Ihre Kunden vereinfacht. Eine einheitliche Plattform für serviceorientierte Testsysteme, durchgängige Maschinensteuerungen oder für die Produktion nach den Anforderungen von Industrie 4.0. Modular, beliebig erweiterbar und unabhängig von bestehender Hardware. Diese Plattform heißt Gamma. Mehr Infos unter Gamma

In der heutigen Zeit sind verfügbare Waren bei Lieferengpässen wertvoller denn je.

In der heutigen Zeit sind verfügbare Waren bei Lieferengpässen wertvoller denn je.

In der heutigen Zeit sind verfügbare Waren bei Lieferengpässen wertvoller denn je. Richtige Lagersoftware managt das erfolgreich für Sie. Aber was bringt eigentlich Lagerverwaltung?

Denken Sie an Ihren Dachboden. Hin und wieder bringen Sie etwas auf den Dachboden für spätere Verwendung. Nach einiger Zeit benötigen Sie die verstauten Sachen und holen diese wieder hervor – wenn Sie diese hoffentlich wiederfinden. Lagerverwaltung.

Für Sie und Ihre wertvolle Ware nur das Beste – Lagersoftware PBW von Proway

Bei Ihrem Dachboden haben Sie sicherlich alles im Blick. Aber angenommen, Ihr Dachboden hat 100.000 und mehr Quadratmeter Stellfläche und Millionen Artikel mit unterschiedlichsten Regalen. Täglich kommen hunderte LKWs, die Gegenstände für den Dachboden bringen, die teilweise auch noch speziell (z. B. gekühlt) zu versorgen sind. Jeden Tag gehen tausende Anfragen für die Dinge auf dem Dachboden ein und Sie versenden an Ihre Familie und Freunde in der gesamten Welt.

Der Aufwand ist enorm und Sie verpflichten alle Nachbarn aus der Straße Ihnen zu helfen. Als Arbeitserleichterung installieren Sie Förderbänder und Automatiklager. Sie besorgen autonome Transportfahrzeuge.

Langsam, aber sicher, haben Sie nicht mehr alles im Blick.

Genau an dieser Stelle kommt PBW als Lagerverwaltungssoftware ins Spiel. PBW überwacht, steuert und koordiniert die gesamte Lagerverwaltung vom Wareneingang bis hin zum Warenausgang. Es überwacht Ressourcen, steuert Automatikkomponenten und kommuniziert mit anderen Systemen. Dabei ist PBW ein modular aufgebautes Standardprodukt mit einer enormen Anzahl an Konfigurationsmöglichkeiten. Damit ist PBW flexibel einsetzbar und erfüllt die Anforderungen jedes beliebigen Lagers, vom hoch automatisierten Logistikzentrum bis hin zu einem Dachboden.

Proway liefert Zukunftstechnologie & keinen Papiertiger.

Proway liefert Zukunftstechnologie & keinen Papiertiger.

Wir als Proway bieten unseren Kunden nicht nur Beratung und Entwicklung, sondern auch Produktlösungen, die ihrer Zeit voraus sind. Digitalisierung, Automatisierung und der Einsatz künstlicher Intelligenz treiben uns dabei täglich voran.

Unser Proway Business World (PBW) ist modular und generisch aufgebaut und der Kunde kann die benötigten Logistikmodule spezifisch auswählen. Der entscheide Vorteil von PBW liegt aber darin, dass PBW durch einfache Konfiguration individuell auf die Geschäftsprozesse des Kunden abgestimmt werden können. Komplexe Abläufe werden zu 80 % abgedeckt und es sind in der Regel keine Entwicklungsarbeiten mehr notwendig. Das spart Zeit, Kosten und weist zudem hohe Qualität und Stabilität auf.

Über die Proway Middleware Gamma können Sensoren, Feldbusse und Systeme mit unterschiedlichen Werkzeugen angebunden werden und mit der Sensorbox Gamma-Zauberwürfel lassen sich über 100.000 Sensoren unterschiedlicher Hersteller anbinden. Das Projekt-, Ticket und Zeiterfassungssystem rundet ihr Projekt ab.

Neben unseren eigenen Produktlösungen bieten wir als Distributor des Herstellers North Atlantic Industries hochwertige Hardwareprodukte unter anderem aus den Bereichen Single-Board-Computer, oder Multifunktions-I/O-Boards an.

Erfahren Sie in den kommenden Wochen mehr über unsere Produktlösungen oder schauen Sie gleich unter: Proway Produkte

Erfolgreich im Team

Erfolgreich im Team

Unsere Projekte erfordern umfangreiches Know-how, Fingerspitzengefühl und praktische Erfahrung. Um unsere hochqualifizierten Teams zu erweitern, suchen wir engagierte und motivierte Mitarbeiter, die sich für IT begeistern können. Wir bieten Ihnen schlanke Hierarchien, neueste Technologien, interessante Projekte u.v.m.

Für nähere Informationen oder Fragen steht Ihnen unser Personalreferent Alexander Schmidt jederzeit gerne zur Verfügung. Wir freuen uns bereits heute darauf, bald von Ihnen zu hören.

Eine gute Woche & beste Grüße

Ihr Proway-Team

Wenn nicht, können wir künftig mit Hilfe der Avedium Standard EDI-Lösung und der Proway NVE Master Engine Abhilfe schaffen.

Diese Lösung ist bereits bei mehreren ERP-Softwareherstellern im KMU- und Enterprise-Umfeld, wie z. B. SAP ECC, SAP Business One, Sage Line 100 und auch M-SOFT integriert. Somit schaffen wir von Proway einen Mehrwert für alle KMU-Unternehmen, denen kein NVE-Modul im Standard zur Verfügung steht.

Erfahren Sie mehr darüber in unserem Workshop: EDI und NVE Master Engine ERP-Integration, leicht gemacht.

Es gibt noch freie Plätze – jetzt anmelden.

Wir freuen uns, Sie zu unserem Webcast am 07.07.2022 um 10.00 Uhr einzuladen und kennen zu lernen. Melden Sie sich an unter: LinkedIn